Transaction Types

•

Transaction types are used to associate

workflows for various phases of sales document processing.

•

The Define Transaction Types window is used to

define both order and line types.

•

For order header the transaction type code will

ORDER and for the lines it will be LINE.

Navigation : OM: Setup > Transactions >Transaction

Types

Transaction Types – Assign Lines

•

Define your line types first. You should define

line types for both order lines and return lines.

•

Once you define the Order Transaction types,

assign the Line Transaction Type using the option Assign Line flows.

Document Sequences

•

Define Document Sequences for automatic or

manual numbering of orders.

•

This step is required. You can define multiple

document sequences that are assigned to different order types.

Navigation : OM: Setup -> Documents -> Define

Document Categories

Whenever we create a new transaction type, a new document

category gets created automatically.

You must define a category for each bill of lading and

packing slip you wish to create.

Navigation: OM: Setup -> Documents -> Categories

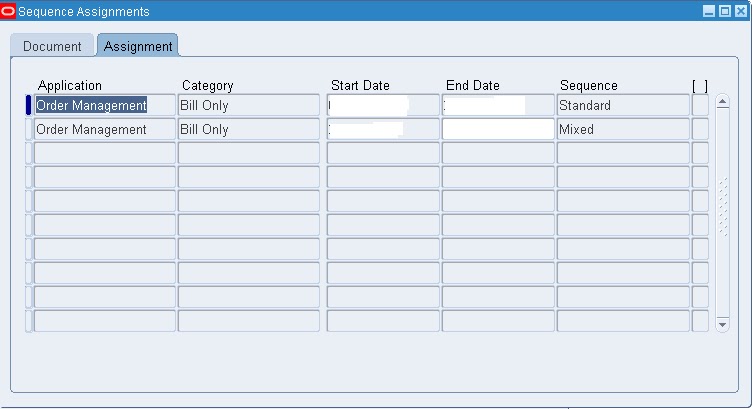

Assign document sequences

After defining document sequences and categories, assign

document sequences to document categories.

Assigning sequences is application and category specific.

You cannot change a document category definition. If you find incorrect information,

create a new category with the correct information, re-assign document

sequences to the new category, and disable the old category.

Navigation : OM: Setup -> Documents -> Assign